Gracilaria is the raw material for the agar industry world-wide. Chile is the largest producer of Gracilaria and Japan is the largest producer of agar. World agar production is currently estimated at 10,000 tonnes per annum, about half of which is from Gracilaria. Japan is the largest producer and consumer of agar. Thailand, Malaysia and Indonesia are major importers of agar as shortages of raw materials and technological expertise are a constraint to agar production in these countries. Vietnam can produce a large quantity of seaweeds (Gracilaria) and has an agar industry, but agar quality is not up to standard. As the price of Gracilaria increased year after year, agar also became expensive, both commercial and bacterial grade. In Japan, South Korea and Taiwan, which are top agar producers, labour and land costs were the reason for the increasing the price of agar. These countries switched production to other Asian countries to increase profits.

The annual world production of agar stands at between 7 and 10,000 tonnes per annum, approximately half of which was produced from Gracilaria and the remainder came mainly from Gelidium (Coppen, 1989). The world agar industry basically uses the following seaweeds :

- 1. Different species of Gelidium harvested mainly in Spain, Portugal, Morocco, Japan, Korea, Mexico, France, USA, People’s Republic of China, Chile and South Africa.

- 2. Gracilaria of different species harvested in Chile, Argentina, South Africa, Japan, Brazil, Indonesia, Philippines, People’s Republic of China (including Taiwan Province), India and Sri Lanka.

- 3. Pterocladia capillace from Azores (Portugal) and Pterocladia lucida from New Zealand.

- 4. Gelidiella from Egypt, Madagascar and India.

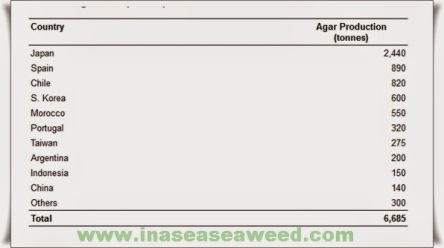

Other seaweeds used include: Ahpheltia plicata from North Japan and the Sakhalin Islands; Acanthopheltis japonica, Ceramiun hypnaeordes and Ceranium boydenii (Armisen and Galatas, 1987). A country breakdown of world agar production is given in Table 1.

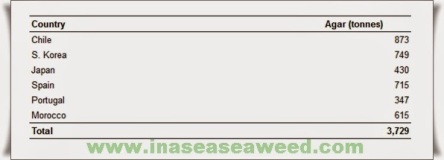

Japan is the largest producer of agar in the world and, in 1987, Japan exported 3,729 tonnes of agar to the countries shown in Table 2.

Table 1 World production of agar, 1984 (tonnes).

|

| Source: Coppen, 1989 |

Table 2: Japanese agar exports, 1987.

|

| Source: Coppen, 1989 |

Japan is highly dependent on imported raw material for its agar production and accounts for most of the world trade in agarophytes (Table 3). The total raw material requirement to produce 7,000 tonnes of agar is around 35,000 tonnes of seaweed, which means that almost a third of the seaweed used enters world trade. The dominant position of Chile as a supplier of Gracilaria means mat, including their own domestic production of agar, they are the world’s largest source of Gracilaria derived agar. Chilean sources estimated the 1985 harvest to be almost 16,000 tonnes (dry weight). The majority of this was collected from the wild but 400 tonnes was cultivated.

The need for greater quantities of agarophytes has encouraged Gracilaria cultivation. Seaweed cultivation has only had limited success, however, and there are still problems to be solved before it can be generally adopted. At present, cultivation is used for industrial purposes in the People’s Republic of China and its Taiwan Province and it is now being initiated in Chile.(Armisen and Galastas, 1987).

The production, utilisation and international trade of commercial seaweeds and seaweed products are important for the countries of Asia-Pacific, especially Gracilaria and agar. In the case of Gracilaria the problem is more difficult to solve. The enzymatic hydrolysis of agar occurs spontaneously even at relatively low moisture contents, but at variable rates depending on the Gracilaria species and its origin.

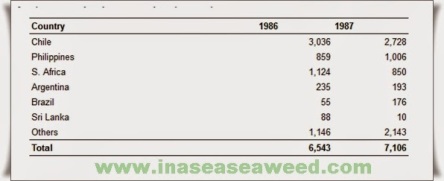

Table 3 Agarophyte (Gracilaria) imports to Japan (tonnes).

|

| Source: Coppen, 1989 |

Gracilaria harvested in India, Sri Lanka, Venezuela, Brazil and generally in warm waters, contains an agar less resistant to enzymatic hydrolysis than the Chilean Gracilaria which is the most stable one known. Nevertheless, the stability of agar contained in Gracilaria is less than that of Gelidium.

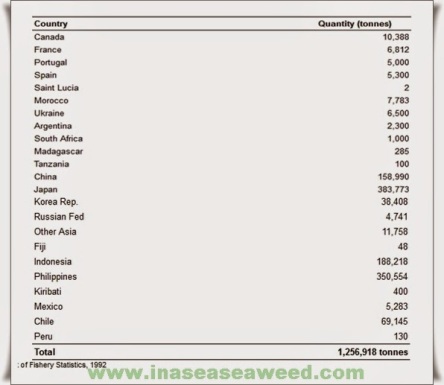

The world production of red seaweeds was 1,256,918 metric tonnes in 1992 (Table 4).

Table 4: World production of red seaweeds in 1992.

|

| Source: FAO Yearbook of Fishery Statistics, 1992 |

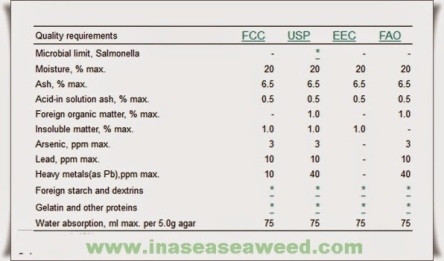

Marketing of industrial agar is done through trading companies operating from Japan, Europe or the United States, where the most important trading companies are located in the area close to New York. There are, however, different standard specifications as shown in Table 5.

Table 5: Standard specifications of agar for FCC, USP, EEC and FAO

(* negative).

|

| Source: Tengtein Y.,and Wattanaoran P., 1989 |

FCC – Food Chemicals Codex

USP – The United States Pharmacopoeia

EEC – European Economic Countries

FAO – Food and Agriculture Organisation of the United Nations,

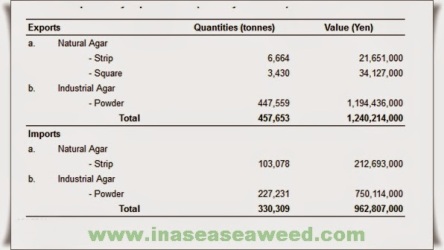

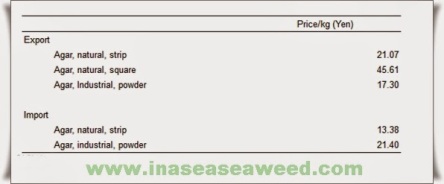

It is difficult to get an idea of the prices of commercial agar because the usual trade statistics list agars with different specifications and applications and therefore with different prices, as shown in Tables 6 and 7.

Table 6: Agar Imported and Exported by Japan in 1986 (January – October).

|

| Exchange rate: 1 US$ = 154.23 Yen Source : Armisen and Galatas, 1987 |

Table 7: Japanese export/ import, average price for agar in 1986.

|

| Exchange rate: 1 US$ = 154.23 Yen Source : Armisen and Galatas, 1987 |

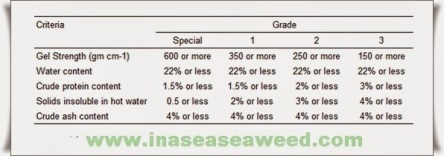

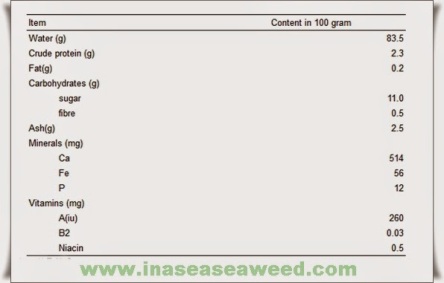

The major parameters of the Japanese Specifications of Processing agar to show the different of qualities of agar, is shown in Table 8. Table 9 shows the chemical composition of Gracilaria.

Table 8: Major parameters of the Japanese Specifications of Processing Agar.

Table 9: Chemical composition (%) of Gracilaria.

|

| Source: Arasaki, S. and Arasaki, T. 1983 |

The Asian nations which would participate in the expansion of Gracilaria production and other agar-bearing seaweeds are Thailand, Malaysia and Indonesia. Vietnam can produce a great quantity of Gracilaria and agar, but they are still problems reaching quality standards for agar in the world market. Vietnam will be developing their Gracilaria production and processing in the near future. Japan, South Korea and Taiwan are now looking for joint ventures in other Asian countries to transfer funding and technology for the agar industry because the labour and land costs in their countries were very high. Vietnam would be especially good for investment because of their high production of Gracilaria.

Exporters of seaweed and seaweed products

Marcel Trading Corp., P O Box 241, Manila, Philippines.

REFERENCES

- Arasaki, S. and Arasaki, T. 1983. Vegetables from the sea to help you look and feel better. Japan Publications Tokyo.

- Armisen, R. and Galatas, F. 1987. Production, properties and uses of agar. In: M°Hugh, D. J. Production and utilisation-of production from commercial seaweeds. FAO Fisheries Technical Paper.

- Chandrkrachang, S. and Chinadit, U. 1988. A New Approach to Seaweed Production and Processing. INFOFISH International No.4/88.

- Coppen, J. J. W. 1989. International Trade in Agar for countries in the Bay of Bengal Region . Songkhla Thailand 23–27 October 1989 BOBP/REP/45

- International Trade Centre UNCTAD/GATT 1981. Pilot Survey of the World Seaweed Industry and Trade. Geneva, Switzerland:(l 11 Page)

- FAO, 1992. Yearbook of Fishery Statistic’s, 1992. FAO,Rome.

- Lima Dos Sandos, C. A., Roessink, G. L., Richards-Rajadural, P. L., Taylor, C. T. and Kano, I. 1988.

- Seaweed processing and marketing in Asia/Pacific. Working paper prepared for the :Seventh Session of the IPFC Working Party of Experts on Aquaculture (Bangkok, Thailand, 1–6 August 1988) UNDP/FAO project RAS/84/027.

- Suo, R. Y. and Qingyin (1992). Laminaria Culture in China. INFOFISH International No./92

- Tangtein, Y. and Wattanaoran P.(1989) “Standard specifications of agar” in Seaweed production and processing Biopolymer Research Unit Srinakarinwirot University Bangkok Thailand (in Thai).